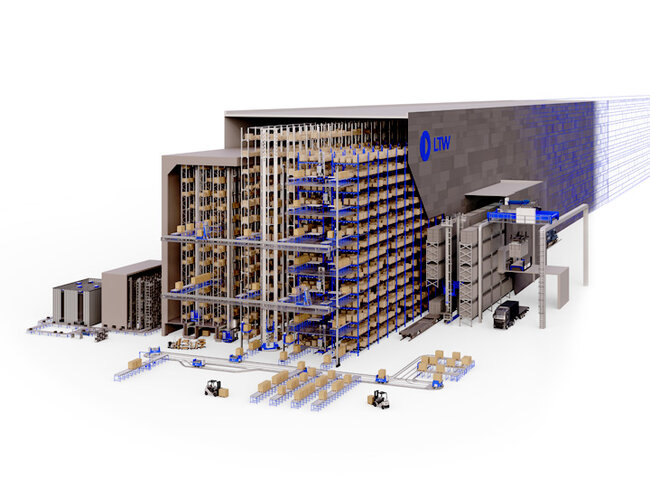

Turnkey solutions from a single source

We focus on integrated turnkey solutions. We implement individual requests and requirements for our customers, regardless of the industry. As part of the Doppelmayr Group, we not only have the scope of a global player, but also the flexibility to concentrate 100% on the solution. Our in-house production is a decisive advantage: we manufacture, assemble, and program all components ourselves. As a result, our employees are intimately familiar with the products, enabling us to offer our customers a unique service at all times. Curious? Then keep scrolling and immerse yourself in the intralogistics world of LTW.

LTW CITY

Whether it's food from the supermarket, medicine from the pharmacy, or a package from an online retailer, we're all used to having the things we need at our fingertips. To achieve this, we need reliable systems and a functioning supply chain. As a full-service provider for intralogistics, we ensure maximum availability in the transport and storage of goods.

Full-service provider

What does it mean to us to be a full-service provider for intralogistics? From consulting and conception to the provision of our products, the implementation of our software and the subsequent support by our service team – we have everything under control for you. Your expert consultant, implementer and advisor at your side.

Components

We provide the products you need to make your project a reality. Our portfolio ranges from storage and retrieval machines to complete automated intralogistics systems. By the way: As a member of the Doppelmayr Group, our products such as storage and retrieval machines, transfer carriages and vertical conveyors comply with the ropeway standard. Under warranty.

LTW Components

LTW Intralogistics Operating System

The software is seen as the heart of every intralogistics system – with perfectly coordinated software, a smooth flow of materials becomes possible. That’s why we combine sophisticated logistics software with modules that are individually tailored to the customer’s expectations. With LTW LIOS we developed a brand-new intralogistics software solution that elevates the interaction between hardware and software to a whole new level.

LTW LIOS

Where it all begins: Receiving is the first stop. Incoming goods are unloaded from the truck and the contents are checked for accuracy. Once the contents have been identified, the goods are entered into the system either automatically via barcode or manually before being stored. Important decisions about the required storage strategy must be made at the first stop.

Our complete solutions provide a smooth process from receiving to shipping. With our conveyor technology, you get a complete intralogistics system, including the automation technology to connect the stacker cranes to the material flow. We implement individual transport solutions for our customers, from continuous conveyors to transfer carts and vertical conveyors to floor conveyors. We have developed the right software to manage and control both manual and automated transport.

Large or small, heavy or light, we can store almost anything for you. Whether your goods are stored in containers, on pallets or on special load carriers. Thanks to our strong production in the background, we will find the optimum solution for you. The most important thing? That we choose the best storage strategy for you and make your storage as efficient as possible. We take into account the various storage strategies, such as FIFO or FEFO, and can also assist you in all matters relating to stocktaking.

Order picking is probably one of the most complex and costly processes within the intralogistics chain. This is because it basically involves the manual or automatic compilation of goods for an order. There are many different types of picking, whereby a basic distinction is made between "goods to person" and "person to goods". Depending on the circumstances within the intralogistics system, one or the other strategy, or a combination of both, may be the optimum solution for you. Let us work together to determine how we can optimize your processes.

Are the goods ready for delivery? Then it's time for shipping. In order to prepare for a smooth shipment, it is important that all previous steps, from receiving to picking, have worked smoothly and without errors. Shipping is the last step before the goods reach the customer. This is the last opportunity to check whether the correct goods are being dispatched – automatically if necessary.