- LTW Intralogistics

- Solutions

- Requirements

- Storage

Storage

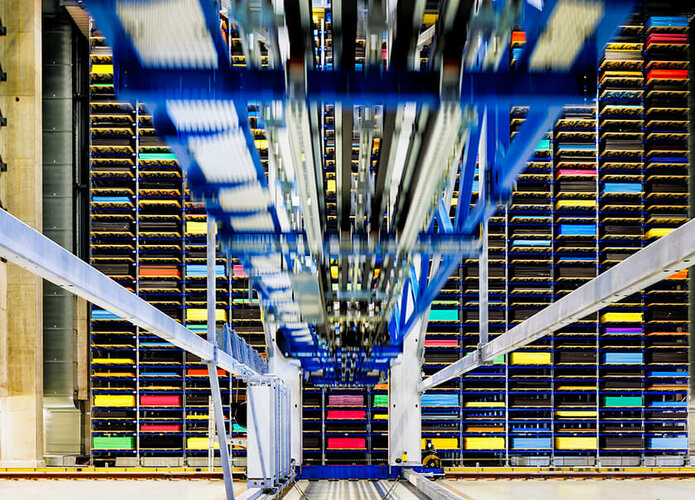

Large or small, heavy or light – we can store almost anything for you. Whether your goods are stored in containers, on pallets or on special load carriers. With a strong manufacturing plant in the background, we will find the best solution for you. The most important thing? That we choose the best storage strategy for you and make storage as efficient as possible. We take into account the different storage strategies, such as FIFO or FEFO, and can also help you with stocktaking.

-

>

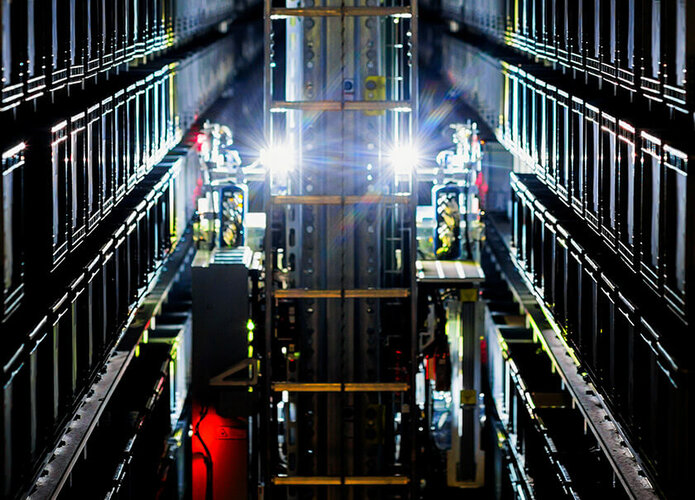

LTW LIOS: Storage

The warehouse management system is a central element of every intralogistics system. It not only cleverly organizes all fully automated processes in the background, but also coordinates the logistical flow of goods for manual operators. This means that both manual, hybrid and fully automated intralogistics systems are supported. As an intelligent link, the LIOS WMS connects all areas of your intralogistics system and thus significantly increases the overall productivity of your company.